| Home | Contact Us | Site Map | Customer list | Technology | Quotation |  |

| Expanded Mesh Production line | Metal Expander | Accessories | Mould & Spare parts | Expanded Mesh | Application |

|

|

||||||||||||||

|

|||||||||||||||

|

|||||||||||||||

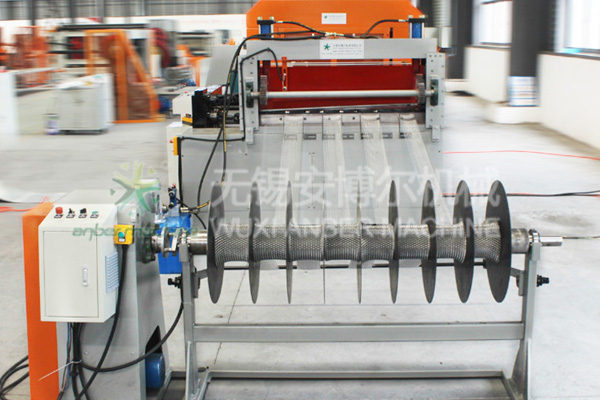

Accessory machine for expanded metal mesh machineSlitting machine

Expanded metal mesh machine

Decoiler

Mesh out from expanded metal mesh machine

Straightening and slitting machine

Recoiler Process flow The expanded mesh slitting line production line firstly use the de-coiler to initiative release galvanized steel plate or stainless steel sheet coil, coil cross the expanded main mesh machine feeding mechanism into the expanding link, expanded mesh machine cross the motor belt drive to send the power to the crankshaft, then drive the mold to do the up and down high speed shearing movement, expanded the sheet steel, then the next levelling and slitting machine expanded the required product size. Finally, automatic re-coiler start recoil the mesh. The production line is applied to expanded mesh automatic continuous production, the main characteristic is high degree of automation, high accuracy, running safely and can reduce man cost, improve production efficient. Structure description and draw The expanded mesh slitting line is composed of de-coiler, expanded metal machine, leveling and slitting machine, automatic re-coiler and electrical controlling cabinet. De-coiler: use motor drive to re-coiler roller¡¯s initiative release, easy to control, simple structure. Expanding machine: Motor drive the belt pulley, send the power to crankshaft, then crankshaft drive the mold to do the up and down high speed running. At the same time, crankshaft¡¯s rotary motion drive the feeding mechanism intermittent feeding, match the expanding action. Leveling and slitting machine contains machine frame, roller leveling, slitting, etc. Motor sent the power to each roller to leveling expanded steel plate, then to the slitting part to shear, worker can adjust the mesh width. Expanded metal mesh production line process: decoiler --- expanding the mesh --- straightening and slitting machine --- recoiling machine --- electrical controlling cabinet |