Rib lath machine

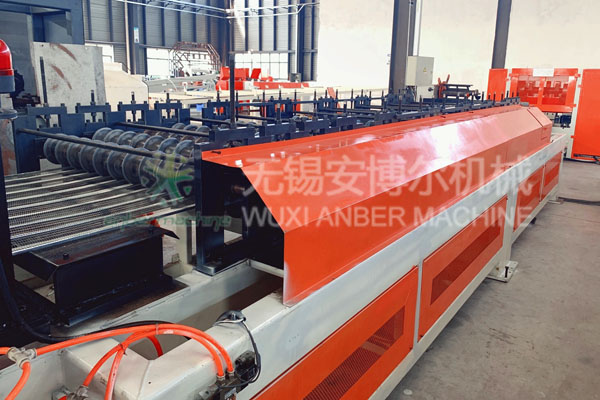

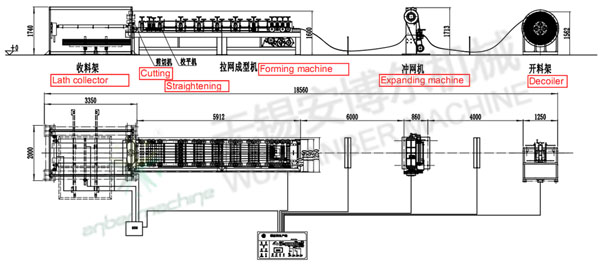

Rib lath machine schedule map

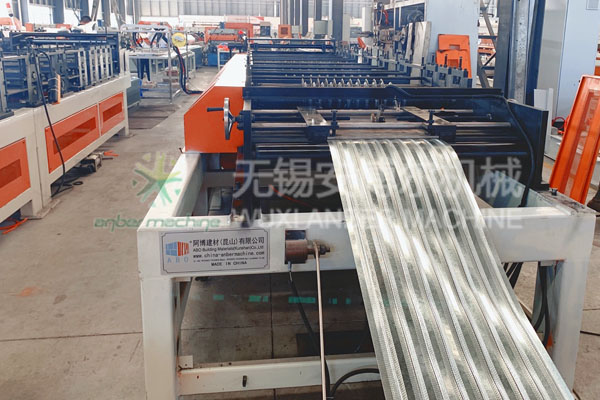

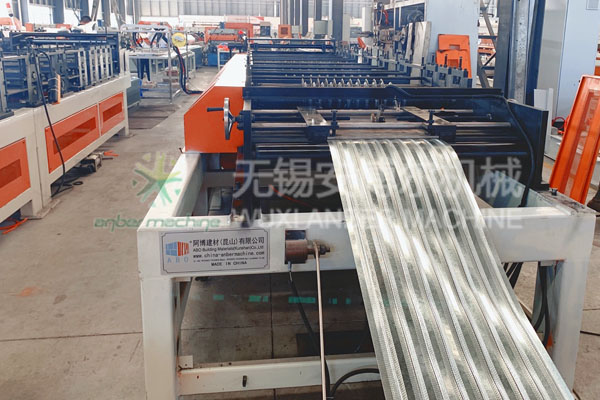

Rib lath production line with lath collector

Description:

Layout: feeding trolley - uncoiler - expanded main machine - roll profiling machine - hydraulic rib lath shearing machine - hydraulic automatic rib lath collect - control cabinet

Material to produce rib lath: 0.3-0.6mm thickness and 420mm width galvanized sheet

Rib lath parameter:

Length: 2493mm, width: 686mm

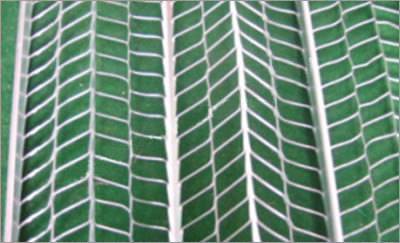

Dimensions: strand width 1.5mm, plate thickness: 0.3-0.6mm, rib distance 98mm, LWD: 10mm, SWD: 5mm

1 set of simple de-coiler (inner dia.: min 400mm; loading weight: 1000kg)

1 set of punching machine

Punching speed: 180 times/min

Punching force: 250KN

Punching mould material: TC53

Overall size: 1325*990*2140mm

1 set of expanded main machine with shearer

Main motor power: 4 kw

Cutting motor: 3kw

mould material: GCR12

Speed: Max. 4m / minutes

Overall size: 5.8m*1m*1.5m

1 set of Feeding device

1 set of collecting Table (Max. Length: 3,000mm)

Occupy area: 12m*2m*2.5m

Layout of rib lath machine:

The finished products (rib lath) :